» Motivation and Background

Thanks to the progress in sensor technology, many low-power-consumption devices have been made available, enabling the possibility of powering the sensors using environmental vibrational energy. Motor vehicles provide a great platform to realize such idea because the motor vehicles employ a huge amount of sensors to monitor driving condition and the vibrations are handy when driving.

Piezoelectric energy harvester is designed in this application. The vibrational energy is converted into electric power most efficiently when the frequencies of energy harvester and environmental vibration match. The typical amplitude and frequency ranges of interest are up to 0.6g and 50 – 200 Hz, respectively.

» Energy Harvester Development

According to the theory of piezoelectricity, the voltage generated from the piezoelectric energy harvester is proportional to the stress in the material. This indicates that a structure with uniformly distributed high stress will yield best energy conversion and result in maximum power output from a specified size.

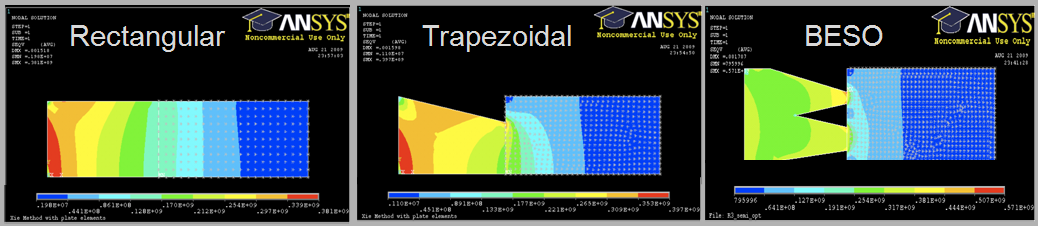

BESO numerical algorithm is utilized to distribute material in the structure such that the stress is uniform under external vibration. BESO takes an initial guess of a structure, discretizes that structure, and calculates the response to a specified forcing. As the algorithm advances, the elements with the lowest strain energies are deactivated and the elements around the highest strain energies are reactivated. Therefore, with the iteration moving on, the stress distribution in the design area becomes increasingly uniform.

Stress distribution for rectangular, trapezoidal, and BESO structures.

Stress distribution for rectangular, trapezoidal, and BESO structures.The models are cantilevered on the left side, loaded on the right side,

and mirrored on the bottom edge (to save computational cost.)

» Device Fabrication

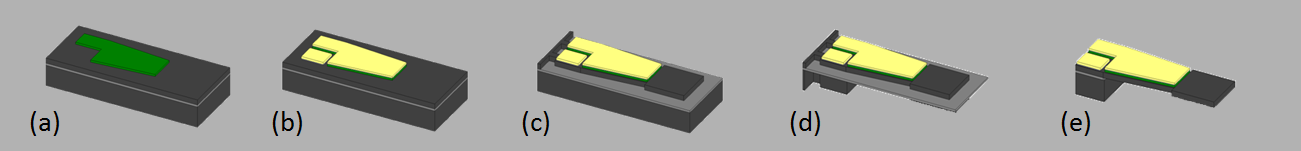

A four-mask fabrication process was designed to manufacture the proposed energy harvester.

- Deposit and pattern AlN of 1-micron thickness on a highly doped SOI wafer.

- Deposit and pattern Ti/Al metal layers for electrical contact.

- Define the structure shape and etch Si away.

- Backside Si etch to form a cantilever beam.

- Etch SiO2 and release the structure from the wafer.

Fabrication process

Fabrication process» Characterization and Improved Design

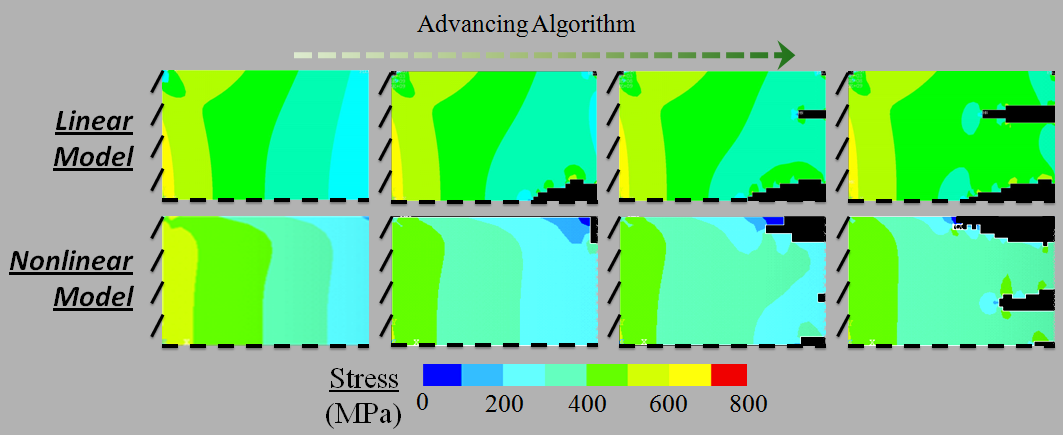

Typical nonlinear behavior was observed at a higher acceleration forcing. This effect limits the maximum power out, while its consequence of an extended bandwidth may be utilized in applications with varying frequencies. The nonlinearity can be attributed to the stress stiffening effect which is crucial when a thin structure is subjected to larg deflection. An improved design with the implementation of nonlinear model yields a trapezoidal-like topology as oppose to structure with central holes generated from linear model. Model verification and power output comparison are ongoing.

Frequency responses of the energy harvesters in deflection (left) and power output for a range of accelerations (right)

Frequency responses of the energy harvesters in deflection (left) and power output for a range of accelerations (right)  Description of BESO material distribution algorithm for both linear and nonlinear cases.

Description of BESO material distribution algorithm for both linear and nonlinear cases.» Reference and Acknowledgement

Reference

- O. M Querin and G. P. Steven, “Evolutionary Structural Optimization (ESO) using a Bidirectional Algorithm”, Eng. Computations. Vol. 15 No. 8, (1998), pp. 1031-1048

Related publication

- M.A. Philippine, C.-F. Chiang, J. Salvia, C. M. Jha, S. Yoneoka, T. Kenny, “Material Distribution Design for a Piezoelectric Energy Harvester Displaying Geometric Nonlinearity,” Solid State Sensors, Actuaters, and Microsystem Workshop, Hilton Head Island, South Carolina, June 6-10, 2010, pp. 451-454.

Acknowledgement

This work is supported by: Audi, a premium brand of Volkswagen Group; the Electronics Research Laboratory, the R&D division of Volkswagen Group of America; the National Science Foundation Graduate Research Fellowship; and the National Science Foundation under Grant ECS-9731293.