|

|

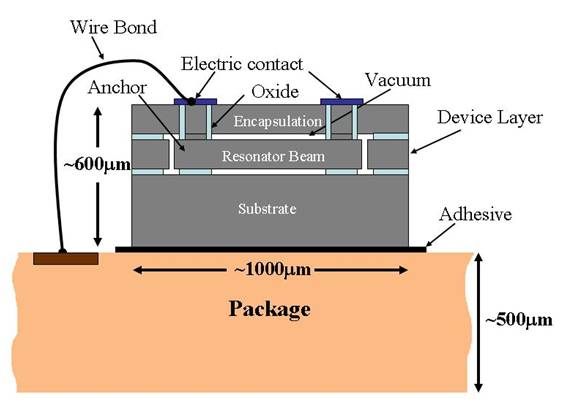

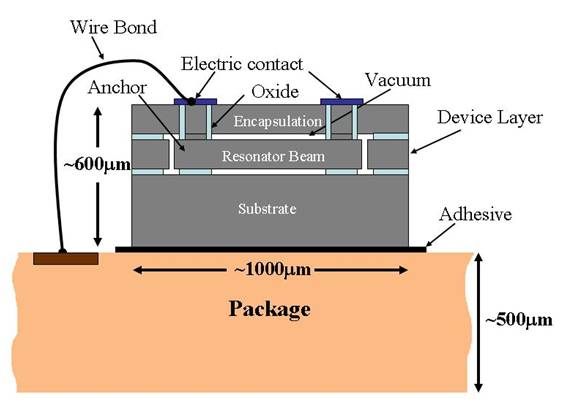

Figure 1 -

Schematic of a typical MEMS resonator chip attached to a package

with adhesive |

|

|

|

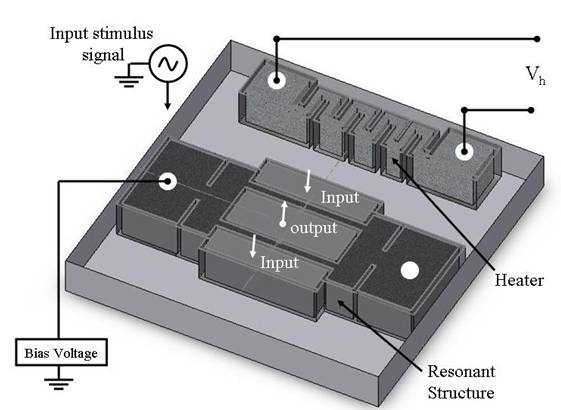

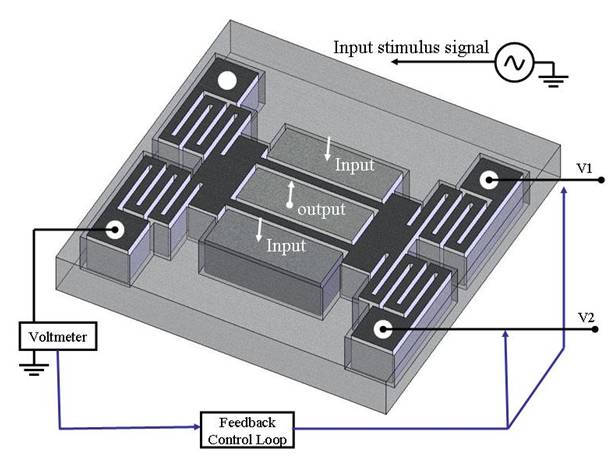

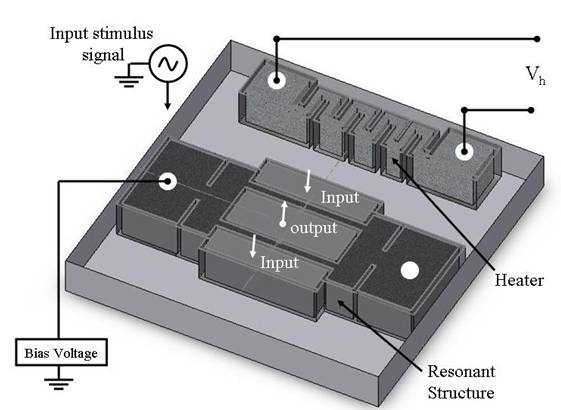

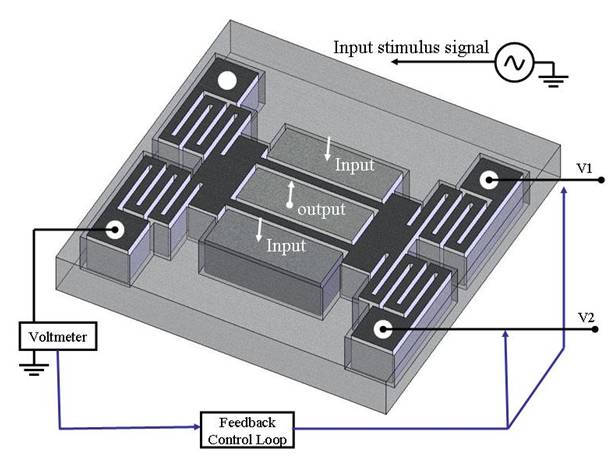

Figure 2 -

Isometric view of the device layer of the chip which contains

resonant structure with input-output electrodes and a resistive

heater. The thickness of the device layer is 20mm.

The resistive heater is used to ovenize the device for temperature

control to compensate the temperature dependence of the resonator

frequency. However this type of heater is not thermally isolated and

hence leads to high power consumption. |

|

|

|

|

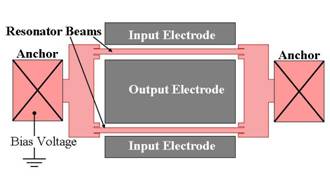

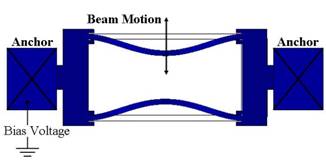

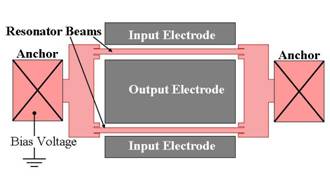

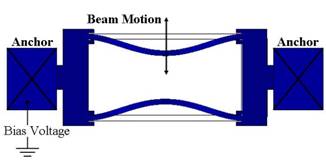

Figure 3 -

Top view of double ended tuning fork (DETF) type resonant structure.

FEM simulation of flexural vibration mode of a DETF (exaggerated

view).

|

|

|

|

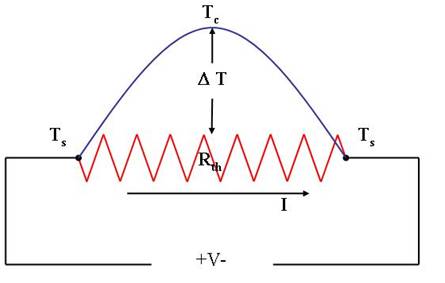

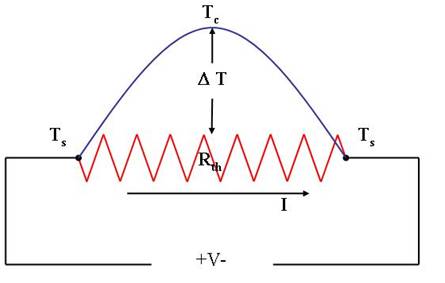

Figure 4 -

Temperature profile along the length of a current carrying resistive

heater having thermal resistance of Rth and electrical

resistance of Re. The above temperature profile shows

that if the resonator is attached at the center of the heater, it

will maximize heating and minimize heat loss, thereby leading to

reduced power consumption for the same temperature rise. |

|

|

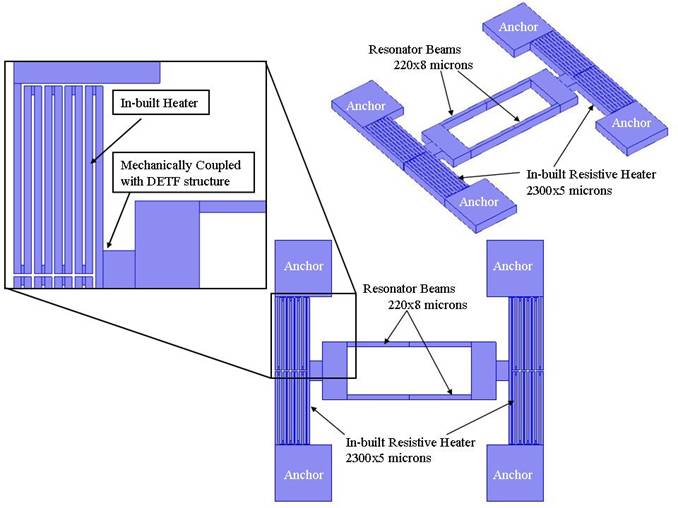

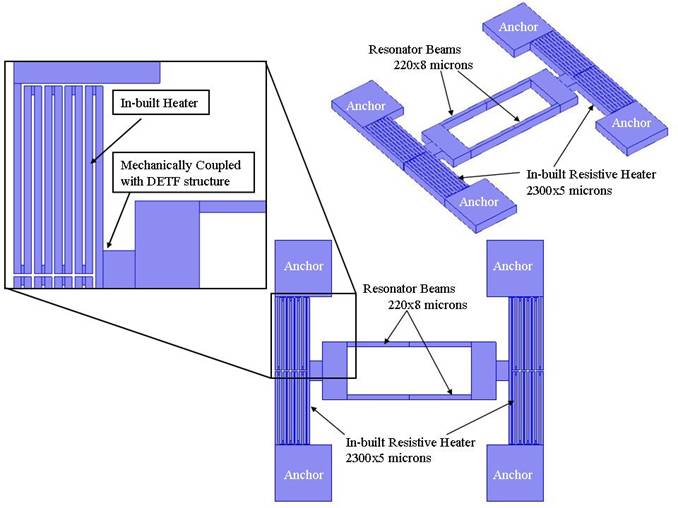

Figure 5 -

Resonator design with local thermal isolation. The heater is

in-built to the DETF such that the resonant structure is attached at

the center of the heater. The entire structure is released except at

the four anchors. |

|

|

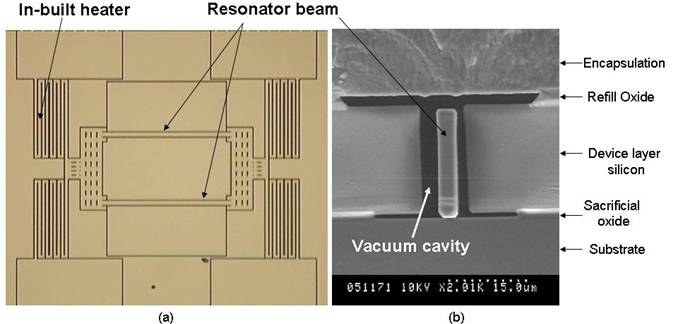

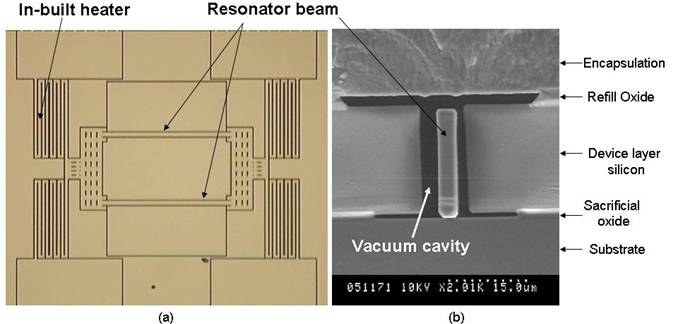

Figure 6 - (a) Optical image of the top view of the

fabricated device before the deposition of the encapsulation layer.

(b) SEM view of the cross-section of a resonator after the

deposition of the encapsulation layer. |

|

|

Figure 7 -

Isometric view of the device layer schematic showing the DETF with

the in-built heater. A stimulus signal is applied to the input

electrode. Heating voltages V1 and V2 are

controlled using feedback control loop to maintain a constant bias

for the resonator. |

|

|

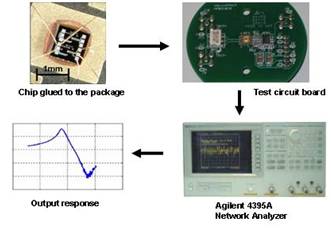

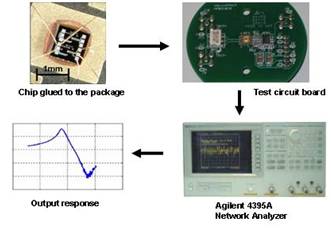

Figure 8 -

Schematic of the test setup for frequency measurement. The device

after being attached into the package is soldered in a PCB to

conduct sweep measurement experiment to get a frequency output

response. |

|

|

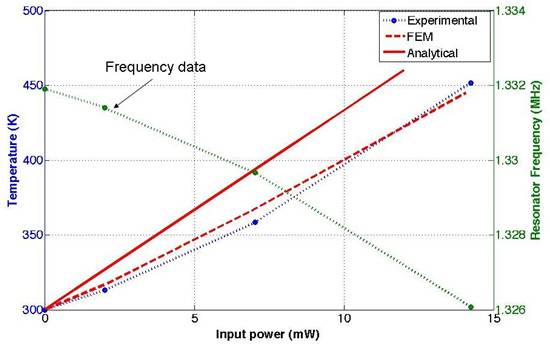

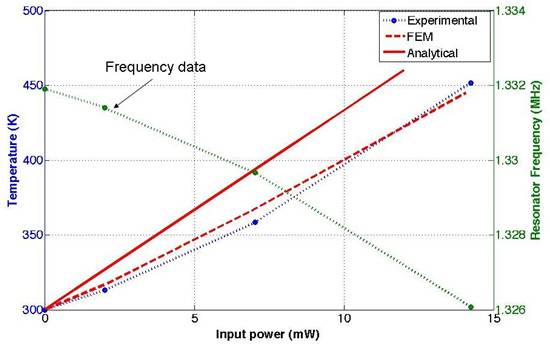

Figure 9 - Variation of resonator frequency due to

joule heating of the in-built heater. The decrease in frequency

(right y-axis) in the above plot corresponds to a temperature rise

(left y-axis, pre-calibrated) with increasing input power.

Experimental results are compared with theoretical estimation. 1-D

analytical results give an upper bound as it is a measure of maximum

temperature at the center of the in-built heater whereas the FEM

output corresponds to the temperature at the center of the resonator

beams. |

|

|

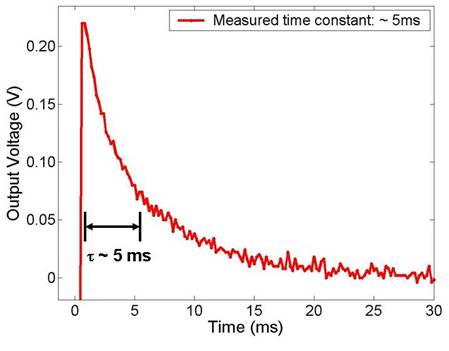

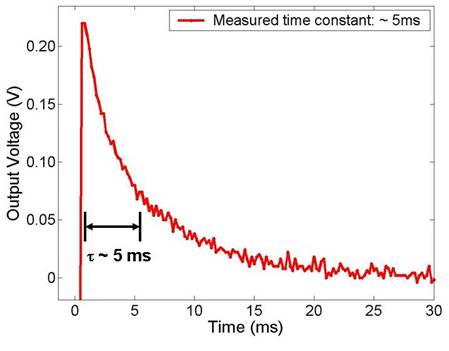

Figure 10 - Thermal

response of resonator with in-built heater. Time constant of

approximately 5 ms was measured using wheatstone bridge with an

input pulse of 4V at 10Hz and a DC offset of 0.5V. Y-axis represents

change in heater resistance due to cooling. |

|

|

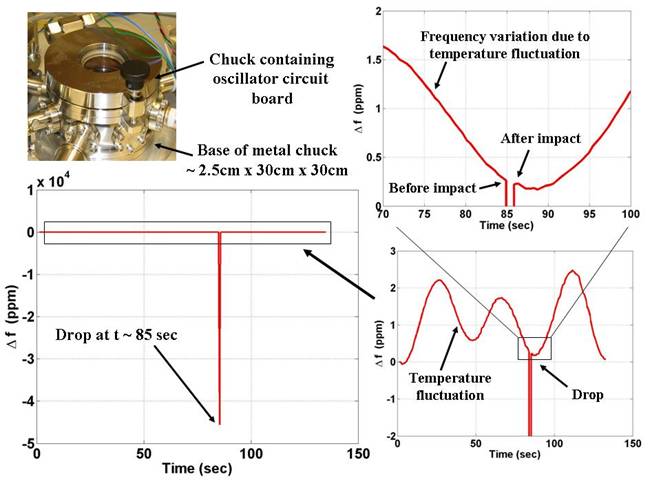

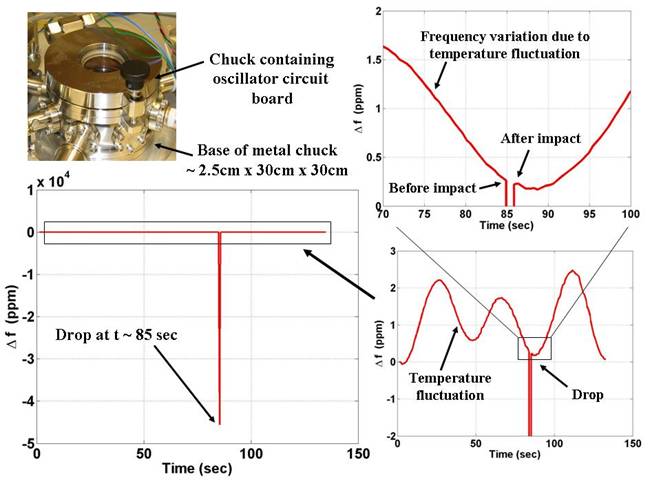

Figure 11 - A

drop test resulted in a temporary change in frequency at the time of

drop. This test is done to check the flexibility of the in-built

heater. In order to increase the thermal isolation, the thermal

resistance of the heater should be as large as possible, however

this also leads to a flexible structure which reduces the mechanical

stability of the resonator. The above drop test confirms that in

spite of large thermal resistance, this structure is mechanically

stable. |

| |

|

An efficient heat delivery and thermal isolation mechanism for a

MEMS resonator has been demonstrated. The in-built heater based

thermal isolation technique serves a dual purpose of localized

heating and thermal isolation, thereby providing maximum heating

with reduced input power. At the same time the device has a small

thermal time constant and high impact resistance because of its

miniature design. Compared to the commercially used quartz crystals

(1-10 Watts and around 30 minutes warm-up time), this work has

demonstrated orders of magnitude improvement in power dissipation

and thermal time constant with a potential for further improvement.

Furthermore this method is simple enough to implement it into any

existing MEMS fabrication process. The described design of

micro-oven is highly suitable for temperature stabilization of

micro-resonators and for very precise control of frequency (< 1.0

ppm) over a large temperature span. |

Supported by the DARPA HERMIT Program |

|

|