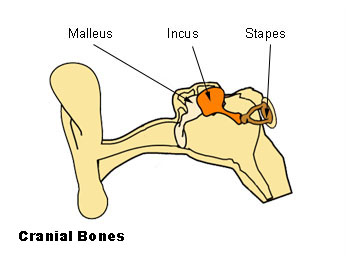

Ear infections cause hearing loss for millions of people around the world through damage to the Ossicles (the small bones) in the middle ear (Fig. 1). Various designs of prosthetic implants for Ossicles are currently used to treat patients with damaged middle ear structures. The prosthetic only approximates the behaviour of the original malleus bone; nonetheless, in most cases middle ear function can be restored such that patient can live normally.

|

| Figure 1 - The Ossicle bones of the human ear. Illustration from SEER Training website. |

Current surgery techniques have a significant drawback in that the optimum length for the malleus implant required for individual patients cannot be determined before the surgery. The prothetics are offered in a range of standard sizes (S M L XL), and the surgeon must decide which size is appropriate during the surgery based on visual inspection of the middle ear after pushing the ear drum aside. The chosen prosthetic is inserted, and the ear drum is re-attached. The results of the surgery are not known until the patient has recovered, typically 4 - 8 weeks. The consequences of using an incorrect size of malleus implant range from poor or nonexistent hearing (for sizes too small) to chronic ear pain and ruptured ear drums (for sizes too large). If the prosthetic is poorly choosen, the patient must wait until the ear has healed to repeat the surgery and receive a different size prosthetic. Even with the optimum size prosthetic, patients typically experience 10 - 20 dB of hearing loss (this is still a significant improvement over having no prosthetic, of course).

The key to developing better malleus prosthetics is to understand the forces transmitted by the malleus and the tissues it interfaces with. The human ear has been extensively studied and modelled, but to date, there have been no direct measurements of the forces on the bones in the middle ear, because the measurement is quite challenging.

Our current project, in collaboration with Dr. Euan Murugasu and the California Ear Institute at Stanford, is to design and create a malleus prosthetic with an imbedded strain gauge. This will directly measure the forces exerted on the malleus prosthetic by the surrounding tissue. This data can then be used to improve ear models and determine the optimum length for the prosthetic.

|

|

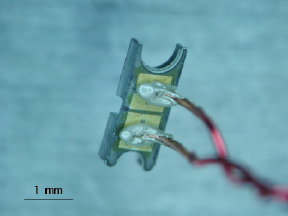

| Figure 2 - Prototype silicon piezoresistive sensors. A US dime is shown for scale. |

|

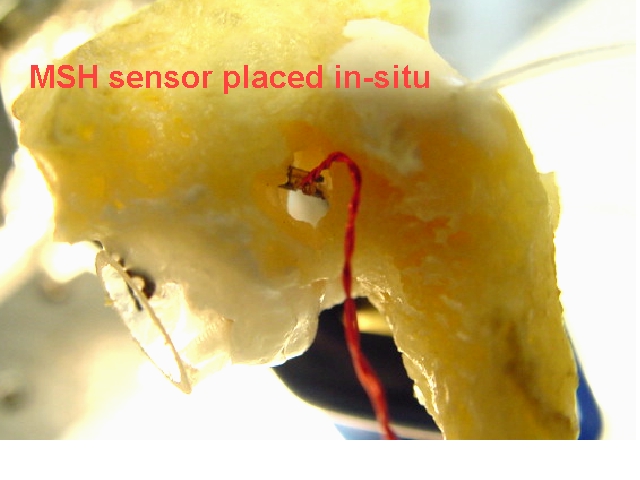

Silicon prosthetics with piezoresistive regions are being fabricated for testing. Some early prototypes of the sensor are shown in Figure 2, and a test insertion of a sensor in a cadaver specimen is shown in Figure 3. Results from measurements in medical specimens are expected in 2004.

|

|

| Figure 3 - Sensor inserted into cadaver specimen. | |