Oven-Controlled MEMS Oscillator (OCMO)

Ryan Kwon. Lizmarie Comenencia, Yunhan Chen

:: Introduction

The In-Plane Oven-Controlled MEMS Oscillator (OCMO) is an epi-sealed dual-mode silicon MEMS resonator operational over a large temperature range. We maintain a localized, elevated operating temperature of the resonator by utilizing the temperature coefficient of frequency (TCf) difference between two excitation modes of the same resonant body as a thermometer, and by integrating a micro-oven in the encapsulation layer. The heater is placed within the device layer to minimize heat loss through the encapsulation layer. Compared with other ovenization schemes that involve an extra thermometer or two separate resonant bodies, the dual-mode ovenization method eliminates temperature gradients between resonators and thermometers, which in turn increases the overall stability over a broad temperature range.Overall schematic of the ip-plane OCMO shown with the SEM image. The heater/anchor sections consists of serpentine beam structure for mechanical/thermal isolation and Joule heating. Figure on right shows the experimental results of the temperature coefficient of frequency of two operating modes. The OCMO is set to operate at the turn-over temperature of ~80C.

:: Design and Method

The design of the device is illustrated above. A square shaped Lamé resonator with suspension frames with in plane device-layer oven is fulled encapsulated in an high vacuum, ultra clean environment. Top electrodes are integrated into the cap layer. The Lamé resonator, in this case, can be simultaneously operated as a plate-bending-mode resonator. Due to the p-type doping and its high concentration (~1E20 cm^3), two distinct TCf characteristics for the Lamé mode and out-of-plane plate-bending mode can be observed as shown.Both modes are driven into resonance simultaneously. The resonant frequencies are tracked and the frequency difference between the two modes is used as a thermometer and provides feedback to the control loop. The Joule heating current passing through the micro-oven in the encapsulation layer is controlled to maintain a constant elevated device temperature.

:: Real-Time Frequency Stability Measurements

Real-time frequency measurements of the OCMO subject to 6℃/min ambient temperature ramps over -40 ~ +60℃ are shown in Figure 3. Measured frequency deviates within a range of ±0.5ppb. No frequency drift or hysteresis is observed over a testing period of 10 hours.Figure 3. Real-time (a) ambient temperature; (b) heating voltage; (c) real-time frequency.

:: Micro-Oven Design and Power Consumption

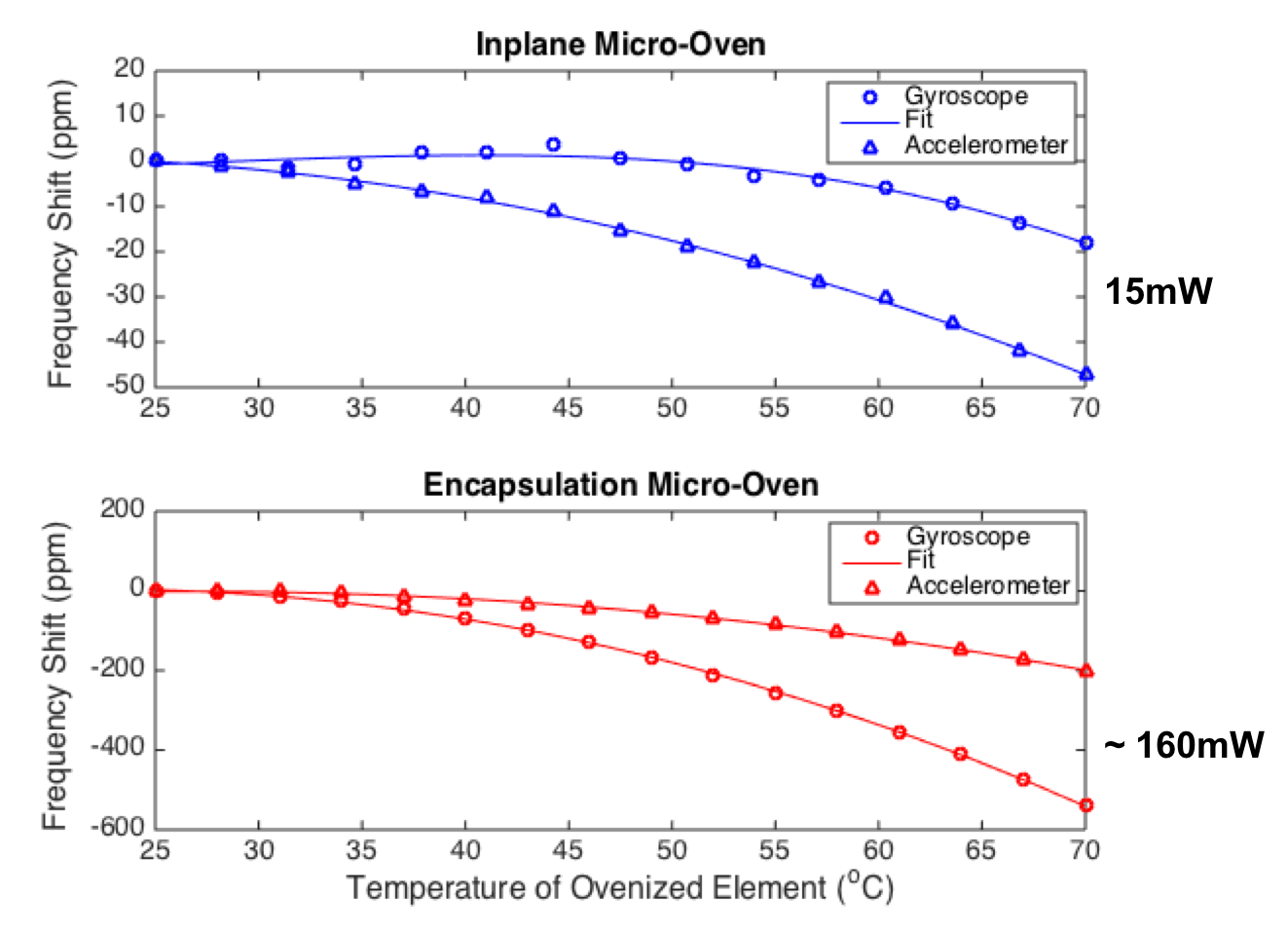

In these results, we use a micro-oven embedded in the encapsulation lid of the structures, while this method is successful in compensating for temperature changes, it requires a great amount of power (approximately 3mW/C). The dissipated heat can affect the stability and performance of other sensors within the encapsulated area due to temperature gradients and thermal stresses. Therefore, it is important to minimize the dissipated heat to reduce the thermal effects in adjacent elements within the die and increase the micro-oven efficiency.We studied the thermal effects of ovenizing clocks and found that a device layer micro-oven, which operates at a tenth of the power of an encapsulation cap-layer micro-oven, has very small effects on the frequency of the other resonators in the die, thus providing good thermal isolation in our structures. Figure 4 shows that the in-plane heater isolation provides more than a 15X reduction of frequency deviation of adjacent sensors.

We are working on iterations of OCMOs with in-plane micro-ovens to reduce the power consumption and thermal effects.

Figure 4. Frequency shift with changes in the temperature of the ovenized element. For comparison, a die with a similar structure and an ovenized resonator with a cap-layer micro-oven as in [1] was heated to approximately the same temperature. Overall, the temperature rise for adjacent devices was 12X smaller for the in- plane micro-oven than for the cap-layer micro-oven for the same amount of temperature increase of the ovenized elements.

:: Publications

[1] Yunhan Chen, Eldwin J. Ng, Dongsuk D. Shin, Chae H. Ahn, Yushi Yang, Ian B. Flader, Vu A. Hong and Thomas W. Kenny, "Ovenized Dual-Mode Clock (ODMC) Based on Hightly Doped Single Crystal Silicon Resonators", 2016 29th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), pp. 91-94, Jan 2016. (Best Paper Award) [LINK][2] Yunhan Chen, Eldwin J. Ng, Yushi Yang, Chae Hyuck Ahn, Ian Flader, and Thomas W. Kenny, "In-situ ovenization of Lamé-mode silicon resonators for temperature compensation," 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), pp. 809-812, Jan 2015. [LINK]

[3] Yunhan Chen (2017) "Temperature Compensation of Epitaxially Encapsulated Silicon MEMS Resonators", Stanford University.

[4] Lizmarie Comenencia Ortiz, Ian B. Flader, Gabrielle D. Vukasin, Dustin D. Gerrard, Saurabh A. Chandorkar, Janna Rodriguez, Dongsuk D. Shin, Ryan Kwon, David B. Heinz, Yunhan Chen, Woosung Park, Kenneth E. Goodson, and Thomas W. Kenny, "Thermal Effects of Ovenized Clocks on Episeal Encapsulated Inertial Measurement Units", To be presented at the 2017 31st IEEE International Conference on Micro Electro Mechanical Systems (MEMS).

Last updated on: Apr 16 2019