High-G Shock Testing of MEMS Devices

David Heinz, Kirsten Kaplan, Daniel Shin, Camille Everhart

Summary - We are developing a series of devices that are capable of withstanding high-g inertial shocks (10,000-50,000g). The robust, hermetic nature of the Stanford Epi-Seal encapsulation process is well suited to high-g shock applications, and we have built our own custom high-g shock test setup for applying shocks to MEMS devices with in-situ measurement capabilities. Our initial results demonstrate that our devices are capable of withstanding these large magnitude inertial shocks, and that some crucial properties remain stable before and after impact.

Introduction to High-G Impacts

High-g impacts are a common cause of failure in many types of mechanical devices. These shocks may be experienced due to accidental misuse (e.g. dropping an iPhone on a concrete sidewalk), or in the course of highly demanding applications, such as military/munitions, manufacturing, construction, and many others. High sensitivity MEMS devices with small, delicate and highly compliant released structures are particularly susceptible to failure under these conditions. As a result it is important to understand the failure modes, and develop innovative solutions to mitigate the problems.

Potential modes of failure include device fracture, stiction, de-anchoring, failure of encapsulation or loss of hermeticity. It is challenging to simulate all of these different modes of failure, especially those which depend upon the interface of different materials and surfaces. Our lab performs repeatable experiments in order to empirically determine the device robustness, and then matches this to simple, reduced order models to gain a better understanding of the processes.

Custom High-G Test Setup

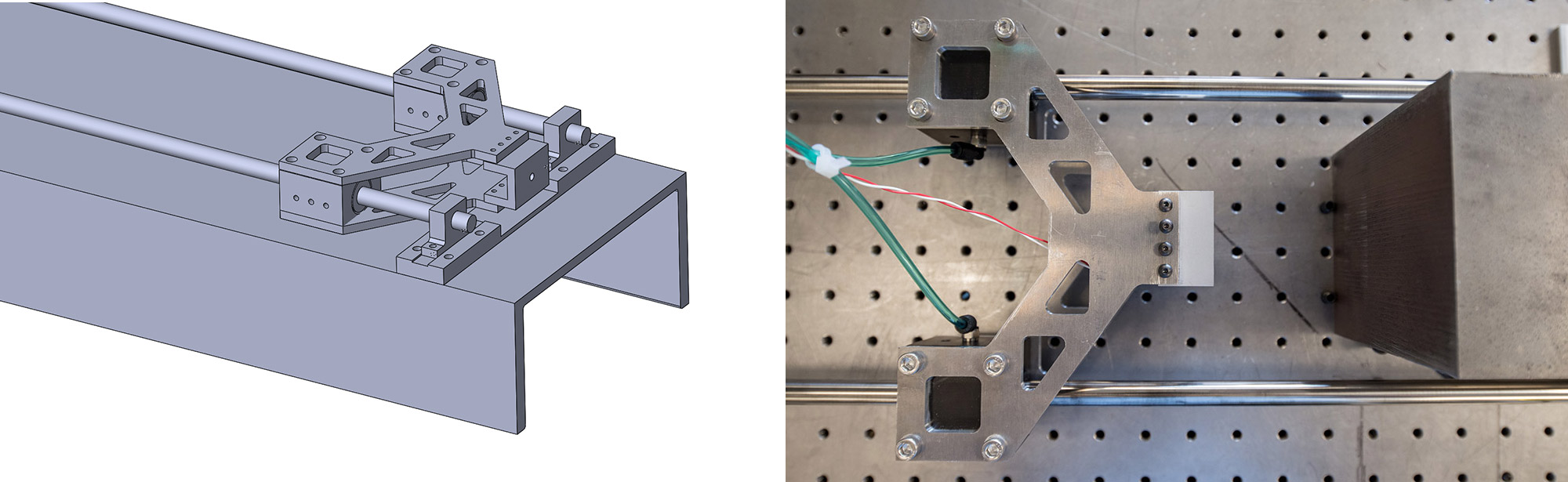

A custom test setup was designed and fabricated to apply high-g shocks to our MEMS devices, with the capability to measure the shock amplitude, and transduce the device throughout the impact. Figure 1 shows the test setup.

Figure 1. Shock test setup CAD drawing (left) and as-fabricated photograph (right).

In order to characterize the performance of the setup, ultra slow motion video and motion tracking analysis were used.

Current Efforts and Results

Our first efforts have been to apply high-g shocks to well-characterized reference devices, such as the standard double-ended tuning fork (DETF). This allows us to limit the uncertainty, and focus on the effect of high-g shocks. Under high-g shocks, the released end of the tuning fork experiences a large displacement, until the travel is limited by impact with the surrounding, fixed sidewalls.

Figure 2. Simulation of DETF motion during 45,000g shock. Sidewall collision would occur here, but is not included in this simulation.

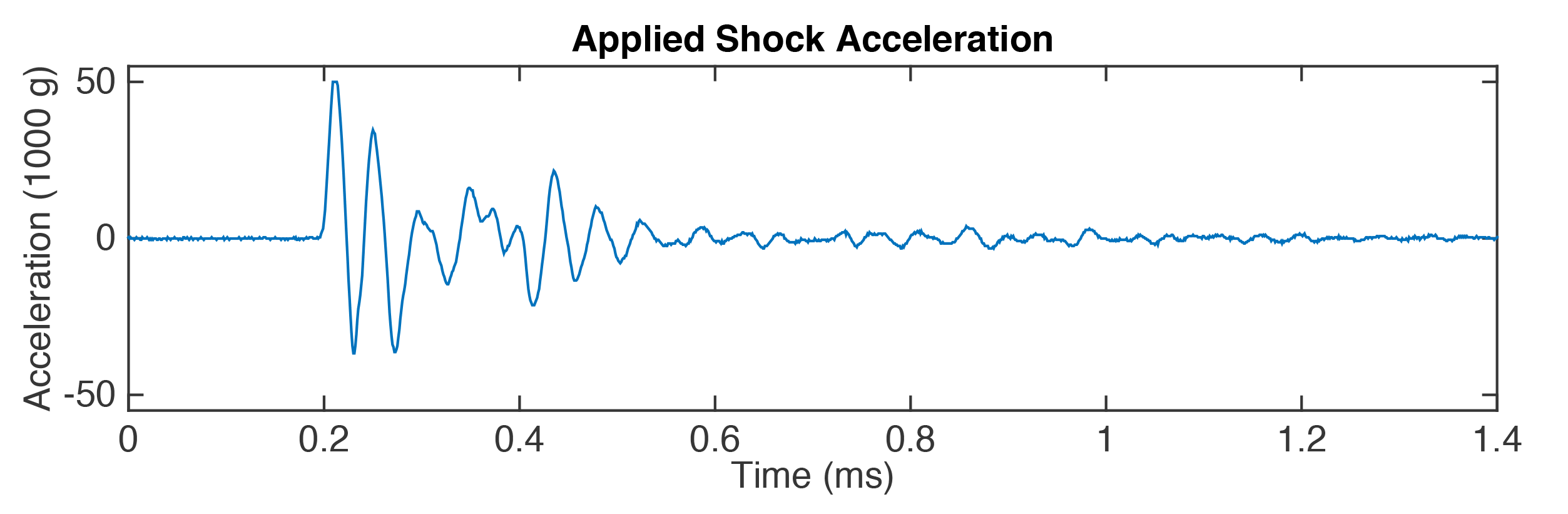

The same conditions from the simulation in fig. 2 are applied to a test device on the custom test set up. Figure 3 shows the applied impact acceleration.

Figure 3. Acceleration applied to DETF for high-g shock test

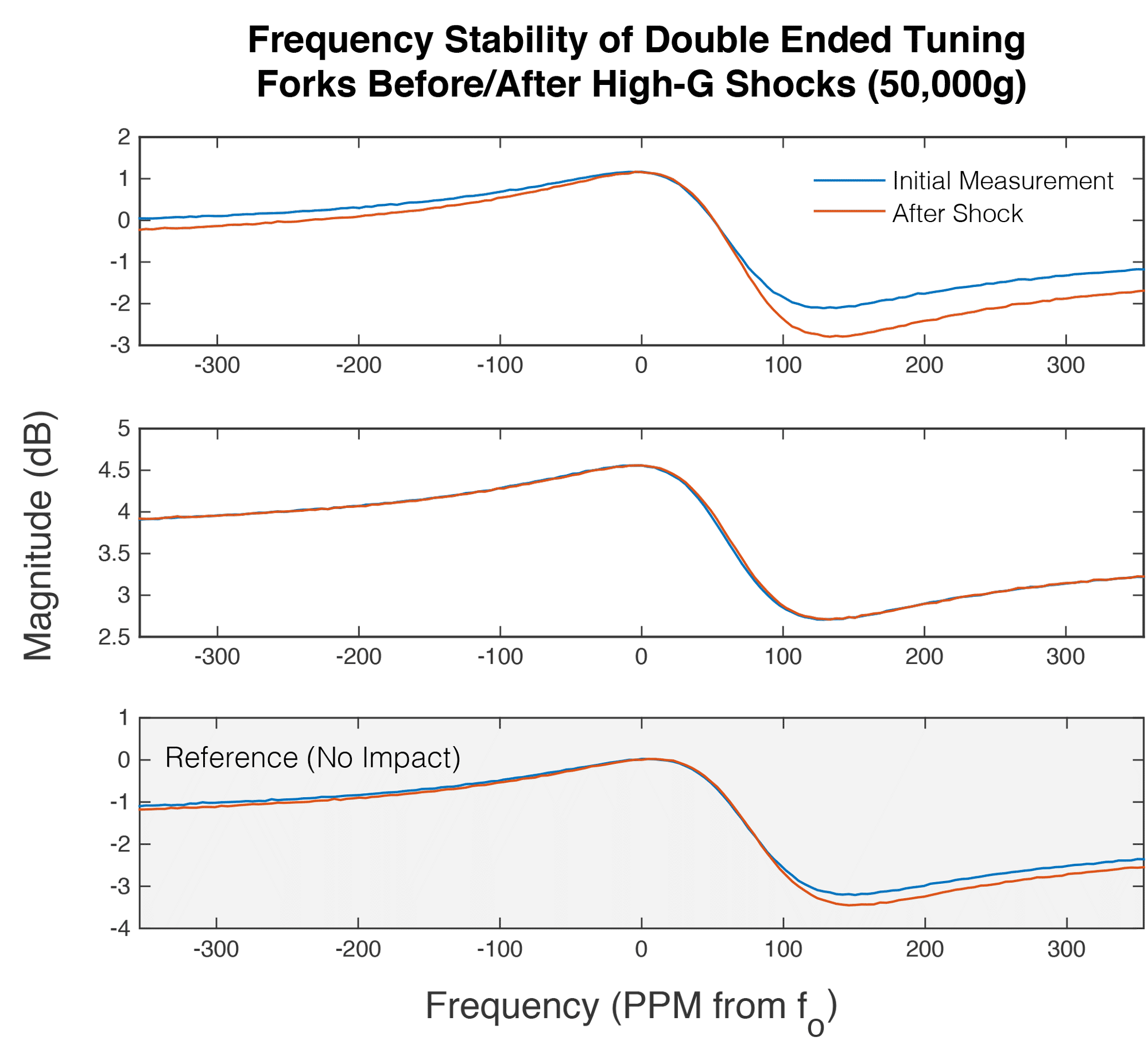

The double ended tuning fork devices consistently are able to survive shocks of these magnitudes. In addition, the device performance is unaffected, to within the tolerance of the measurement. The resonant frequency and quality factor remain constant despite the high-g impact. This result is repeatable across numerous devices of this and similar designs.

Figure 4. Frequency sweep results for DETF before and after high-g shock.

Upcoming Research Efforts

Efforts are continuing in developing more advanced understanding of device behavior during high-g impacts. High-g testing is being conducted on a variety of devices including inertial sensors, surface adhesion test devices, atomically thin films and timing references. In addition, continued testing is revealing more about the motion of the device during impact and energy dissipation mechanisms.

[1] D. B. Heinz, V. A. Hong, Y. Yang, C.-H. Ahn and T. W. Kenny, "High-G (>20,000g) inertial shock survivability of epitaxially encapsulated silicon MEMS devices," 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), pp. 1122-1125, (2017)