ALD Thermal Accelerometer

Camille Everhart, Kirsten Kaplan, Martin Winterkorn, Karen Kim

INTRODUCTION

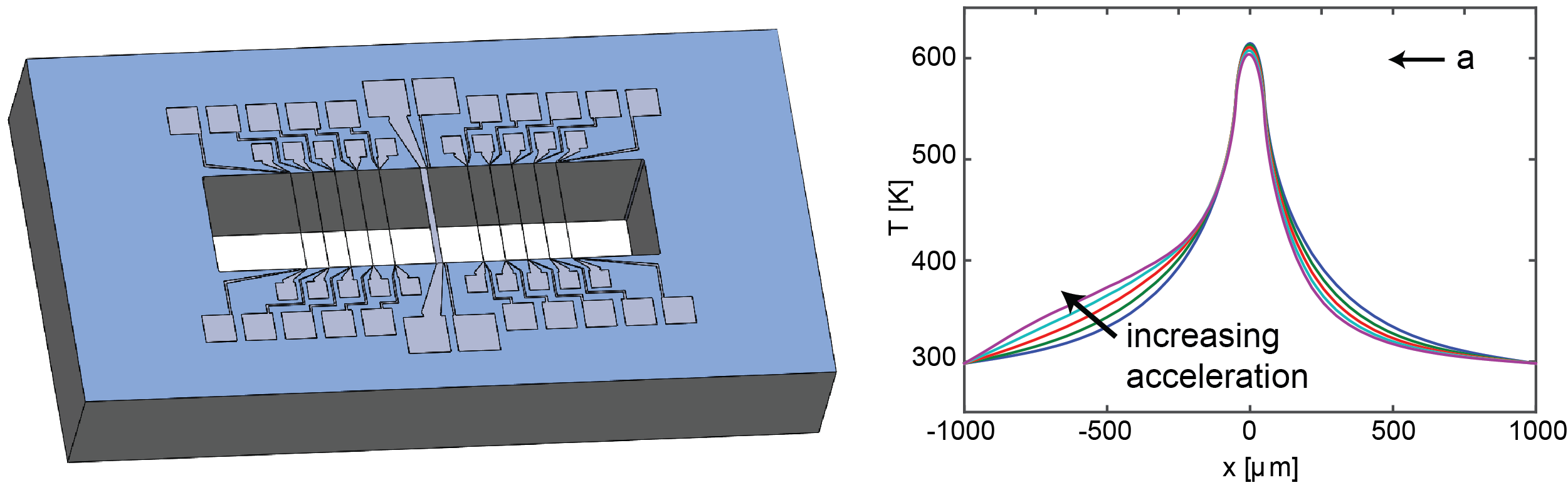

Conventional accelerometers detect acceleration by sensing the displacement of a proof mass, an approach that inherently limits operation and survival of the device during high shocks. Thermal accelerometers rely on a thermal sensing mechanism and have no moving parts; as a result these accelerometers are not subject to the same shock limitations. The basic thermal accelerometer design consists of a central heating beam and associated symmetric thermometer array suspended across a cavity (Figure 1a). Joule heating of the central beam locally heats the air to create a symmetric thermal distribution in the cavity. An applied acceleration results in a temperature asymmetry, with the magnitude of the acceleration detected as a temperature difference in symmetric thermometers (Figure 1b).

Figure 1. (a) Schematic of thermal accelerometer, consisting of a central heating beam surrounded by symmetric thermometer arrays. (b) Temperature distribution in the cavity for several applied acceleration, with higher accelerations showing more temperature asymmetry.

Our suspended structures are fabricated with platinum deposited by plasma enhanced atomic layer deposition (PEALD). The resulting thin-film structures have high stability and temperature coefficient of resistance (TCR), both desirable properties for temperature sensing. Furthermore the smaller size factor enabled by PEALD reduces the thermal time constant, thereby increasing the bandwidth.