|

metal |

|

seal oxide |

|

cap epipoly |

|

refill oxide |

|

functional epipoly |

|

refill oxide |

|

Si substrate |

Motivation: For many MEMS devices the final stages of fabrication can be the most critical and challenging steps in the process flow, requiring expensive handling and packaging techniques that must be specialized for each device. One goal of this work is to demonstrate a complete device and packaging process, whereby a wafer emerges from fabrication with devices released and hermetically sealed in at the wafer-scale. This approach reduces die space for packaging and allows the use of conventional post-processing, such as dicing, wire bonding, and use of standard handling techniques.

Approach: To accomplish a wafer-scale encapsulation, we have developed methods for oxide filling of MEMS devices prior to the conventional Hydrofluoric Acid (HF) release step, thick EpiPoly encapsulation, HF vapor release, and oxide sealing of the encapsulation. This relies on conventional film growth tools with slight process modifications, and a unique HF vapor etcher developed at Bosch. To demonstrate the capabilities of this encapsulation method, we have constructed accelerometers and resonators within these encapsulations, and the characteristics of the resonators are presented below. We show that it is possible to encapsulate crystalline or polycrystalline elements within this process. We believe that this packaging approach has the potential to become vital for fabrication of resonators, inertial sensors, and many other MEMS devices which do not require physical access from outside the package.

|

| ||||||||||||||

| Fig. 1 Encapsulation process flow | |||||||||||||||

|

|||||||||||||||

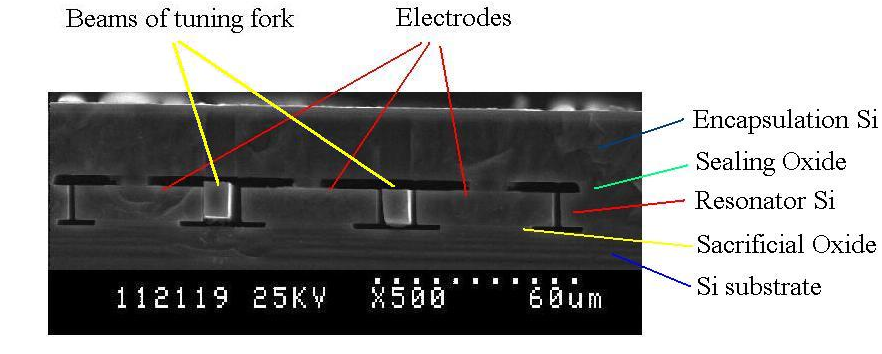

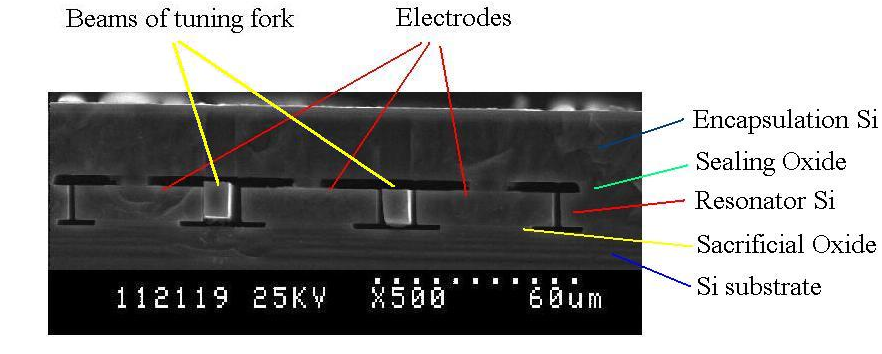

| Fig. 2 SEM cross section of encapsulated micromechanical resonator | |||||||||||||||

|

|||||||||||||||

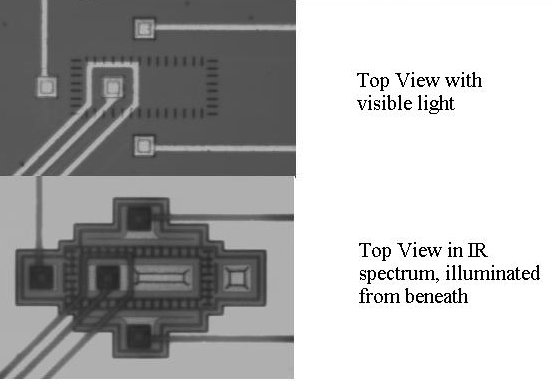

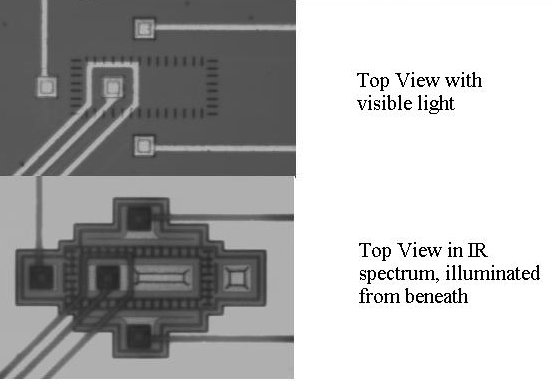

| Fig. 3 Top view of encapsulation and view through cap to encapsulated tuning fork using Infrared camera and backside illumination. | |||||||||||||||

|

|||||||||||||||

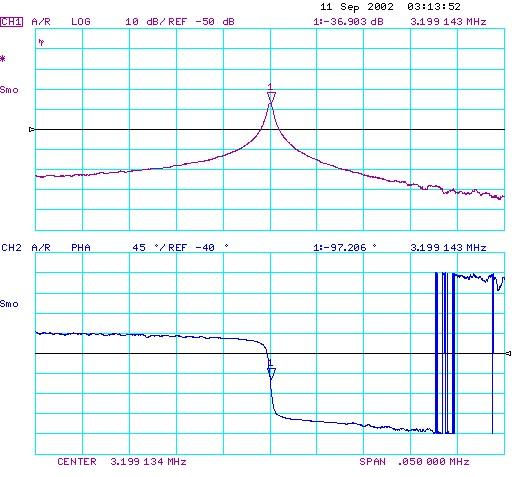

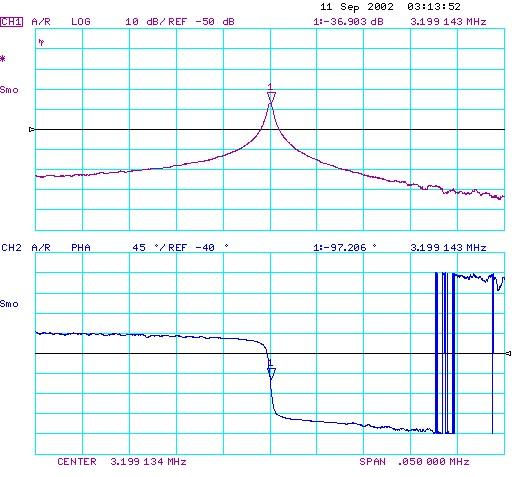

| Fig. 4 Gain/Phase plot of working encapsulated resonator with fres ≈ 3MHz and Q ≈ 10,000 | |||||||||||||||