Design Division, Department of Mechanical

Engineering, Stanford University

dlaser@micromachine.stanford.edu

|

|

|

|

|

|

| Silicon Electroosmotic Micropumps:

Design and Theory of Operation Prototypes, Performance, and Applications |

Collaborators:

Prof. Tom Kenny, Stanford Micro Structures and Sensors Laboratory Prof. Juan Santiago, Stanford Microfluidics Laboratory Prof. Ken Goodson, Stanford Microscale Heat Transfer Laboratory |

| Theory of Operation |

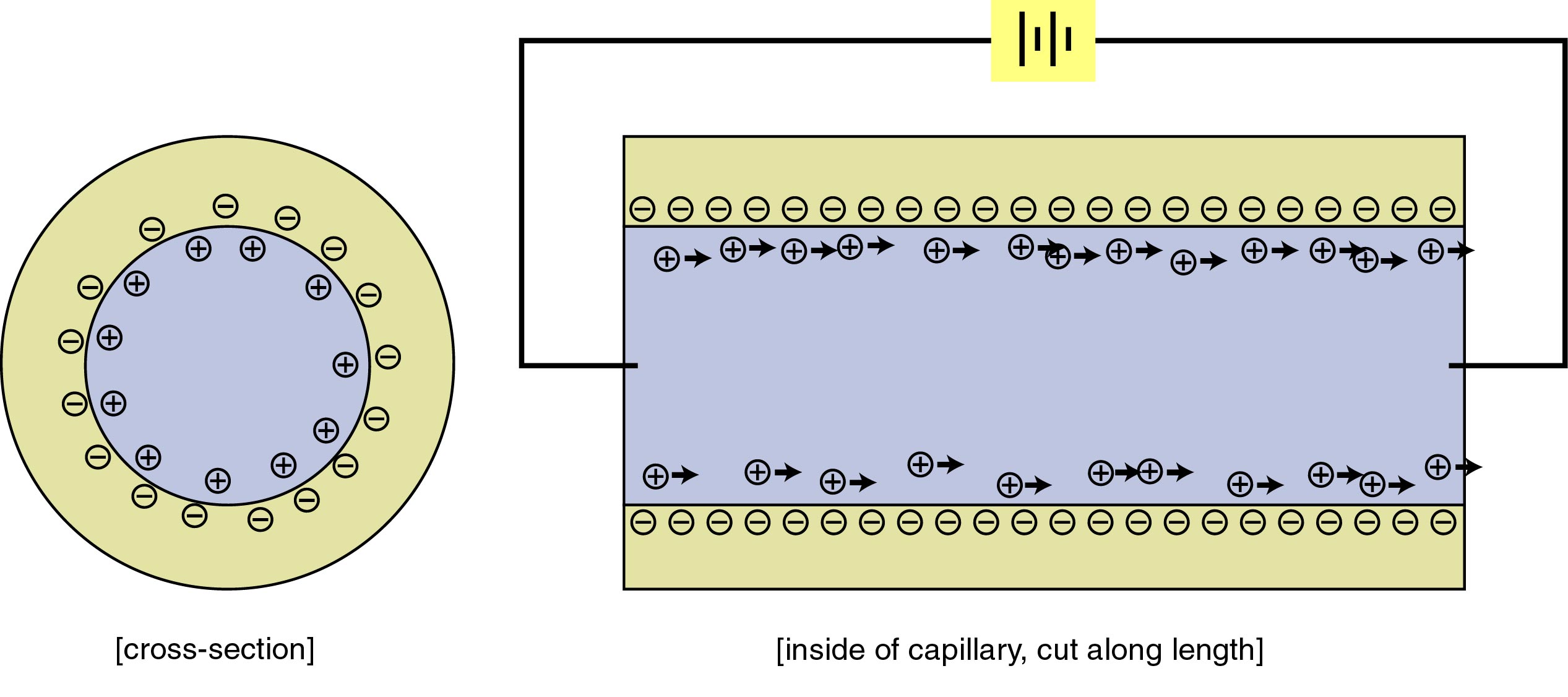

| Electrochemical reactions at an interface between two phases (e.g. liquid and solid) give rise to a class of phenomena described by the term electrokinetics. Electrokinetic effects are used in a variety of engineering applications, including miniaturized systems for performing chemical and biological analyses. These systems are often referred to as micro total analytical systems, or mTAS. An electrokinetic effect known as electroosmosis can be used to pump liquids at the microscale. My research focuses on combining electroosmotic pumping with silicon micromachining technology to produce new systems for use in mTAS, for thermal management in integrated systems, and for other applications. |

|

Applying an external electric field along the length of a capillary generates electroosmotic flow. The capillary is effectively turned into a pump - an easy-to-make pump with no moving parts. These features make electroosmosis very appealing for use in microscale systems for performing chemical and biological analysis, such as those developed by Aclara Biosciences and Caliper Technologies. A 1 kV electrical potential applied along a 1 cm length of a water-filled capillary with an inside diameter of 10 microns can be expected to produce electroosmotic flow at around 1.5 mm/sec (corresponding to a flow rate just under ten nanoliters per minute) against 1 kPa of back pressure--performance that is more than adequate for many micro analysis systems. |

|

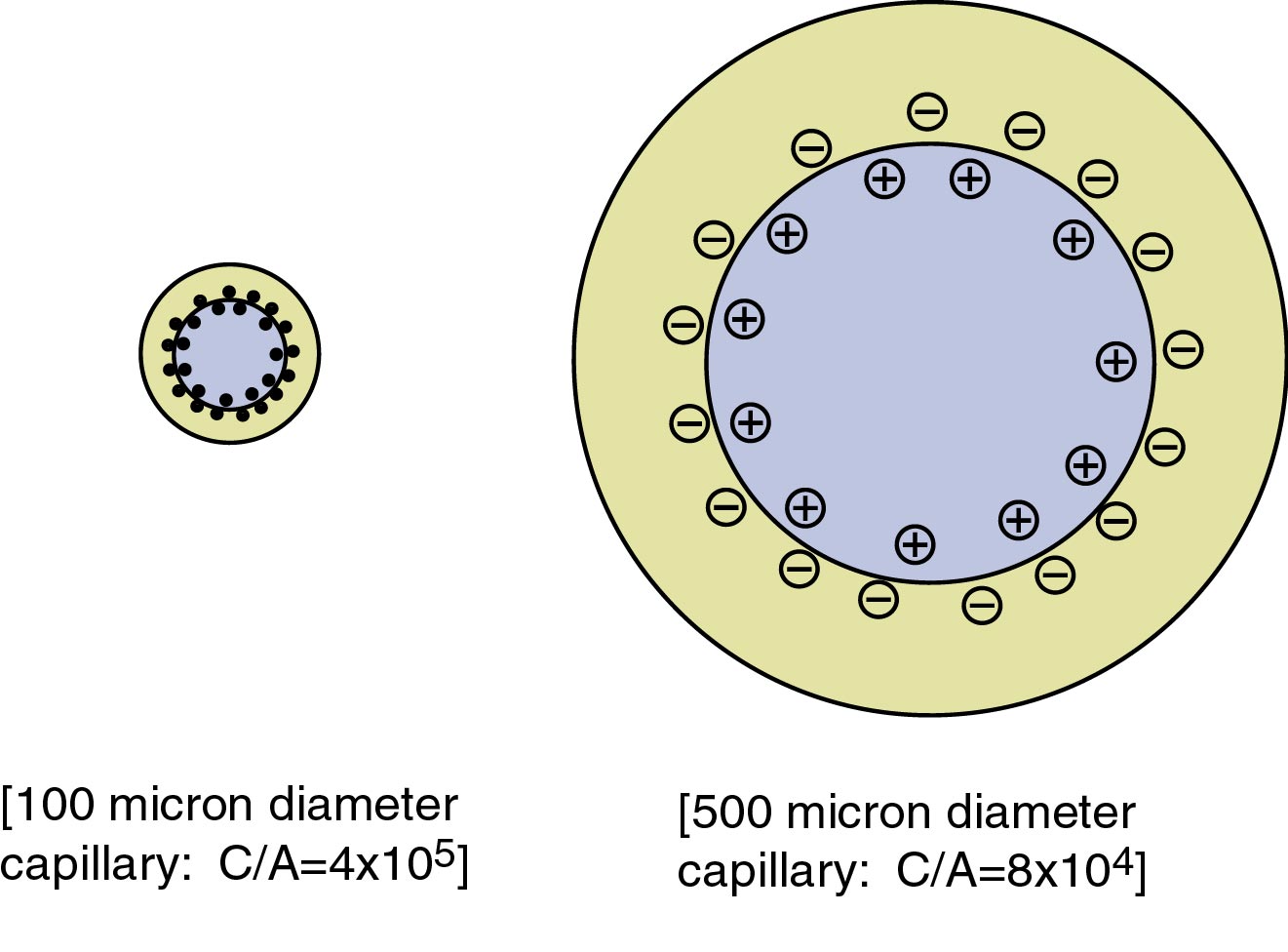

Can electroosmosis be used as the basis for micropumps suitable for more demanding applications, such as thermal management in microchips? To generate higher flow rates, a capillary (or similar structure) with a large pumping cross-sectional area is required. Because electroosmosis depends on the electric double layer at the liquid-solid interface, however, increasing the capillary size (and thereby reducing the ratio of the capillary's circumference to its cross-sectional area) diminishes pump performance. |

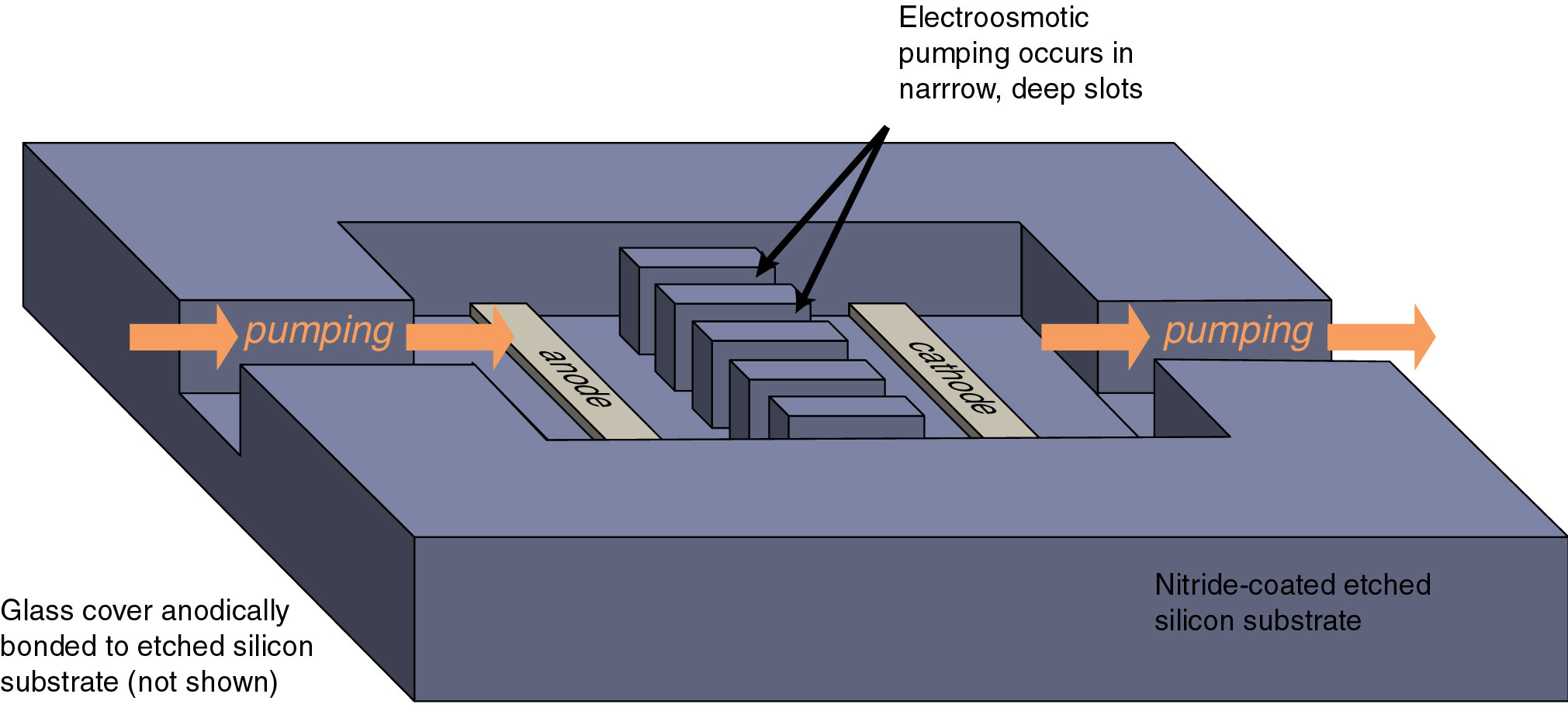

| Silicon Electroosmotic Micropump Design |

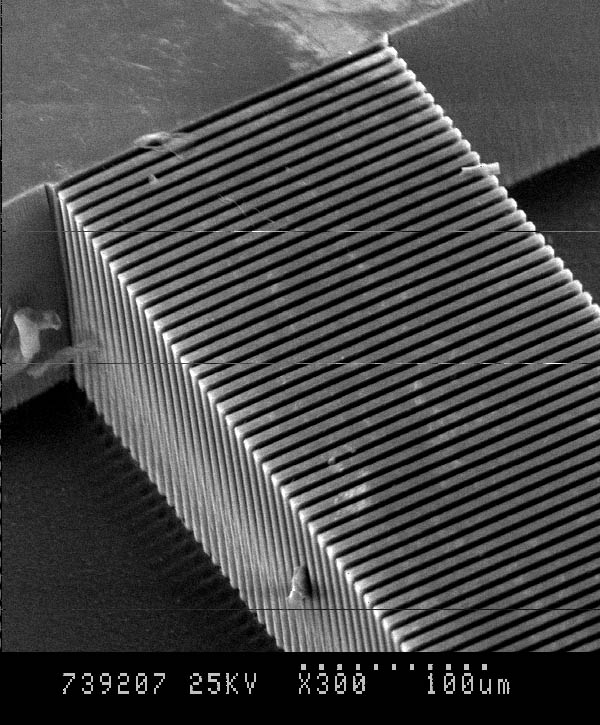

| We solve the pressure-flow rate problem using silicon micromachining. Slots with a large perimeter to cross-sectional area ratio are deep-etched in a silicon substrate. The pumping cross-sectional area (and therefore the flow rate) can be made arbitrarily large by increasing the number of slots. Prototype pumps with 1000 slots generate flow rates of around 30 ml/min. |

|

|

| Illustration of the basic silicon electroosmotic micropump structure. A silicon nitride coating sufficiently passivates the silicon substrate as to allow operation at several hundred volts. | Scanning electron micrograph showing a portion of the pumping area of a silicon electroosmotic micropump. In this pump, deep-etched slots 3 mm wide are spaced at 20 mm intervals. |

| Patents issued and pending. |

| Question? Comments? dlaser@micromachine.stanford.edu |