|

Silicon Microelectromechanical Resonators

|

|

Double-Ended

Tuning Fork Resonator (DETF): Vibration of beams produces a timing signal

|

Silicon micromechanical

resonators provide a periodic signal that can be used as a frequency

reference in timing applications.

Silicon

resonators have the potential to displace the $12 billion timing market

currently dominated by quartz crystals.

More detailsÉ

|

|

Temperature Dependence Problem

|

|

Silicon

Resonator Behavior: The

frequency of a silicon resonator decreases with increasing temperature.

|

Commercialization

of silicon frequency references has been hindered by the strong temperature

dependence of silicon resulting in frequency instability.

Unlike

quartz crystals, whose temperature dependence can be reduced by an

appropriate cut of the crystal, the silicon structure does not possess a

temperature dependent cut.

More detailsÉ

|

|

Compensation Methods

|

|

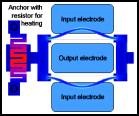

Active Temperature

Compensation: The temperature of the resonator is maintained at a constant

temperature using joule heating of a serpentine resistive structure

|

Compensation

methods to reduce the temperature dependence of frequency can be broadly

characterized as passive or active.

Active

compensation schemes rely on characterization of the temperature dependent

behavior and circuitry to correct for temperature changes.

Passive

compensation schemes seek to reduce the inherent temperature dependence of

the resonator.

More detailsÉ

|

|

Material Compensation

|

|

Composite Resonator:

Cross-section of composite beam with sense and actuation electrodes on

either side.

|

Material

compensation is a passive compensation method and is the primary focus of

my research.

Temperature

compensation is achieved by creating composite structures containing both

silicon and silicon dioxide.

Composite resonators show a 20X reduction in the temperature

sensitivity of frequency that is comparable to quartz crystal resonator

behavior.

More detailsÉ

|

|

Single Wafer Encapsulation Process

|

|

Encapsulated

Resonator: SEM of a DETF showing resonator under the surface of a wafer

with top metallization.

|

Composite

resonators were fabricated in a CMOS compatible, single-wafer encapsulation

process. This high-yield process encapsulates resonators in a hermetic

environment whose long-term stability has been established.

More details...

|

|

Enabling Technologies

|

|

High

Accuracy Temperature Sensor:

Multiple composite resonators with different temperature

dependencies are combined to achieve a extremely temperature sensitive beat

frequency.

|

Material

compensated composite resonators can be combined with active temperature

compensation schemes to create high stability frequency references.

More detailsÉ

|

|

|