Epi-Seal MEMS Process

Gabrielle Vukasin, Christopher Cameron

:: Epi-Seal

Earlier work in our group under the DARPA HERMIT program resulted the development of a encapsulation process for silicon MEMS. The epi-seal encapsulation process [1, 2] is a unique wafer-level encapsulation for silicon structures that is free of contamination and native oxide. Such an encapsulation has been demonstrated to be crucial to achieving high stability [3, 4] with no observable fatigue [5, 6]. This established low cost/high yield process is currently being used by SiTime with great success for the fabrication of silicon MEMS resonators.

References

[1] A. Partridge, M. Lutz, "Episeal pressure sensor and method for making an episeal pressure sensor," U.S. Patent #6928879, Aug 16, 2005.

[2] R. N. Candler, et al., "Long-Term and Accelerated Life Testing of a Novel Single-Wafer Vacuum Encapsulation for MEMS Resonators," JMEMS, Vol. 15, No. 6, pp. 1446-1456, 2006.

[3] B. Kim, et al., "Frequency stability of wafer-scale film encapsulated silicon based MEMS resonators," Sensors and Actuators A: Physical, Vol. 136, No. 1, pp. 125-131, 2007.

[4] E. J. Ng, et al., "Stability measurements of silicon MEMS resonant thermometers," 2011 IEEE Sensors Proceedings, pp. 1257-1260, 2011.

[5] S. Yoneoka, et al., "High-cyclic fatigue experiments of single crystal silicon in an oxygen-free environment," 2010 IEEE MEMS, pp. 224-227, 2010.

[6] V. A. Hong, et al., "High-stress fatigue experiments on single crystal silicon in an oxygen-free environment," Hilton Head 2012, pp. 453-456, 2012.

[1] A. Partridge, M. Lutz, "Episeal pressure sensor and method for making an episeal pressure sensor," U.S. Patent #6928879, Aug 16, 2005.

[2] R. N. Candler, et al., "Long-Term and Accelerated Life Testing of a Novel Single-Wafer Vacuum Encapsulation for MEMS Resonators," JMEMS, Vol. 15, No. 6, pp. 1446-1456, 2006.

[3] B. Kim, et al., "Frequency stability of wafer-scale film encapsulated silicon based MEMS resonators," Sensors and Actuators A: Physical, Vol. 136, No. 1, pp. 125-131, 2007.

[4] E. J. Ng, et al., "Stability measurements of silicon MEMS resonant thermometers," 2011 IEEE Sensors Proceedings, pp. 1257-1260, 2011.

[5] S. Yoneoka, et al., "High-cyclic fatigue experiments of single crystal silicon in an oxygen-free environment," 2010 IEEE MEMS, pp. 224-227, 2010.

[6] V. A. Hong, et al., "High-stress fatigue experiments on single crystal silicon in an oxygen-free environment," Hilton Head 2012, pp. 453-456, 2012.

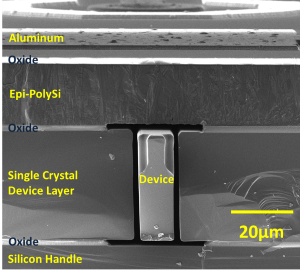

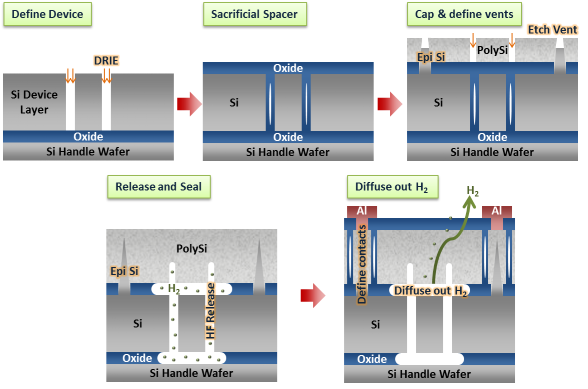

:: Fabrication Process

The standard epi-seal process is as illustrated on the right. First, the MEMS structure is defined by etching trenches in the device layer of a silicon-on-oxide (SOI) wafer using deep reactive ion etching (DRIE). A sacrificial oxide layer is deposited to fill the trenches and to provide a oxide spacer layer above the device. Contacts are etched in the oxide and a silicon layer is deposited in an epitaxial reactor. This is crystalline silicon where there is a crystalline seed and epitaxial polysilicon where there is oxide. Vents are then etched into this cap and vapor HF is used to etch the oxide to release the device. After a high temperature hydrogen bake in an epitaxial reactor to remove contaminants and native oxide, a second layer of epitaxial silicon is deposited, sealing the device in a clean cavity. Thereafter, electrical isolation and contacts are defined. The pressure in the cavity is further lowered by diffusing hydrogen in the cavity out, achieving a pressure of a few Pa.Epi-Seal variants

Standard Epi-Seal (Hot Dog): Only gaps ~1um can be defined. [1]Large Gaps (Grand Canyon): Wider gaps possible using wafer bonding. [2]

Narrow Gaps: Gaps of 200-300nm can be achieved. [3]

Oxide Coated Silicon Structures (Krispy Kreme): For passive temperature compensation. [4]

Localized Degenerately Doped Regions: For passive temperature compensation. [5]

Top Electrodes: Electrodes can be defined in the cap in addition to in-plane electrodes. [6]

References

[1] R. N. Candler, et al., "Long-Term and Accelerated Life Testing of a Novel Single-Wafer Vacuum Encapsulation for MEMS Resonators," JMEMS, Vol. 15, No. 6, pp. 1446-1456, 2006.

[2] A. B. Graham, et al., "A Method for Wafer-Scale Encapsulation of Large Lateral Deflection MEMS Devices," JMEMS, Vol. 19, No. 1, pp. 28-37, 2010.

[3] E. J. Ng, et al., "Ultra-high aspect ratio trenches in single crystal silicon with epitaxial gap tuning," Hilton Head Conference, pp. 182-185, 2013.

[4] R. Melamud, et al., "Temperature-Insensitive Composite Micromechanical Resonators," JMEMS, Vol. 18, No. 6, pp. 1409-1419, 2009.

[5] E. J. Ng, et. al., "Localized, degenerately doped epitaxial silicon for temperature compensation of resonant MEMS systems," Hilton Head Conference, pp. 2419-2422, 2013.

[6] C.-F. Chiang, et al., "A single process for building capacitive pressure sensors and timing references with precise control of released area using lateral etch stop," 2012 IEEE MEMS, pp. 519-522, 2012.

[1] R. N. Candler, et al., "Long-Term and Accelerated Life Testing of a Novel Single-Wafer Vacuum Encapsulation for MEMS Resonators," JMEMS, Vol. 15, No. 6, pp. 1446-1456, 2006.

[2] A. B. Graham, et al., "A Method for Wafer-Scale Encapsulation of Large Lateral Deflection MEMS Devices," JMEMS, Vol. 19, No. 1, pp. 28-37, 2010.

[3] E. J. Ng, et al., "Ultra-high aspect ratio trenches in single crystal silicon with epitaxial gap tuning," Hilton Head Conference, pp. 182-185, 2013.

[4] R. Melamud, et al., "Temperature-Insensitive Composite Micromechanical Resonators," JMEMS, Vol. 18, No. 6, pp. 1409-1419, 2009.

[5] E. J. Ng, et. al., "Localized, degenerately doped epitaxial silicon for temperature compensation of resonant MEMS systems," Hilton Head Conference, pp. 2419-2422, 2013.

[6] C.-F. Chiang, et al., "A single process for building capacitive pressure sensors and timing references with precise control of released area using lateral etch stop," 2012 IEEE MEMS, pp. 519-522, 2012.

:: Platform for Integrated MEMS

There is much interest in integrating microelectromechanical systems (MEMS) today for cross-sensitivity compensation or for applications such as inertial navigation. For example, many silicon MEMS devices are sensitive to temperature and having a thermometer on chip allows for temperature compensation techniques to be applied. Some MEMS devices such as magnetometers may also be sensitive to acceleration and having an accelerometer on chip can then allow for compensation. Integrating these compensated timing references and sensors on the same chip is essential for high stability and low noise sensors. A wide variety of such devices have been fabricated on the epi-seal platform::: Timing References

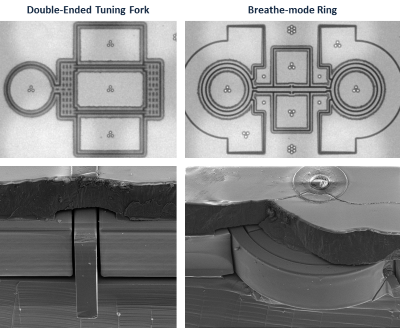

Our group has demonstrated capacitively actuated silicon MEMS resonators with high stability due to the clean encapsulation afforded by epi-seal. Flexural mode resonators as well as bulk mode resonators [1-3] have been demonstrated within the low pressure epi-seal environment of < 1 Pa.

Our group has demonstrated capacitively actuated silicon MEMS resonators with high stability due to the clean encapsulation afforded by epi-seal. Flexural mode resonators as well as bulk mode resonators [1-3] have been demonstrated within the low pressure epi-seal environment of < 1 Pa.

References

[1] Z. Pan, A. Partridge, M. Lutz, "Breath-mode ring resonator structure, and method of designing, operating and using the same," U.S. Patent #7323952, Jan 29, 2008.

[2] S. Wang, et al., "Encapsulated mechanically coupled fully-differential breathe-mode ring filters with ultra-narrow bandwidth," Transducers 2011, pp. 942-945, 2011.

[3] S. Wang, et al., "Nonlinearity of hermetically encapsulated high-Q double balanced breathe-mode ring resonator," 2010 IEEE MEMS, pp. 715-718, 2010.

[1] Z. Pan, A. Partridge, M. Lutz, "Breath-mode ring resonator structure, and method of designing, operating and using the same," U.S. Patent #7323952, Jan 29, 2008.

[2] S. Wang, et al., "Encapsulated mechanically coupled fully-differential breathe-mode ring filters with ultra-narrow bandwidth," Transducers 2011, pp. 942-945, 2011.

[3] S. Wang, et al., "Nonlinearity of hermetically encapsulated high-Q double balanced breathe-mode ring resonator," 2010 IEEE MEMS, pp. 715-718, 2010.

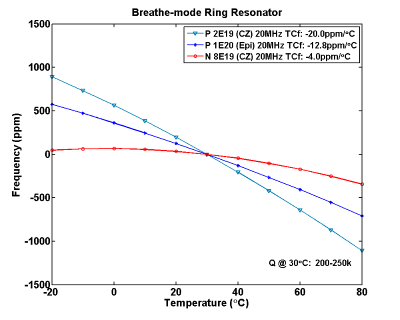

Temperature Stability

Eldwin Ng

Since the stiffness of silicon varies over temperature, any temperature change results in a shift in the resonant frequency (~-30ppm/C). This is not acceptable for many applications and numerous methods have been developed to compensate for this variation. Silicon resonators have been coated with silicon oxide for passive compensation [1], and electronic phase-locked loop techniques have been developed for more accurate compensation [2]. More recently, degenerate doping of silicon has been shown by other groups to reduce the temperature dependence [3-4], and work is on-going to develop temperature-insensitive epi-sealed resonant systems.

References

[1] R. Melamud, et al., "Temperature-Insensitive Composite Micromechanical Resonators," JMEMS, Vol. 18, No. 6, pp. 1409-1419, 2009.

[2] J. C. Salvia, et al., "Real-Time Temperature Compensation of MEMS Oscillators Using an Integrated Micro-Oven and a Phase-Locked Loop," JMEMS, Vol. 19, No. 1, pp. 192-201, 2010.

[3] A. K. Samarao, F. Ayazi, "Temperature Compensation of Silicon Resonators via Degenerate Doping," IEEE Trans. Elec. Dev., vol. 59, no. 1, pp. 87-93, 2012.

[4] T. Pensala et al., "Temperature Compensation of Silicon MEMS Resonators by Heavy Doping," Int'l Ultras. Symp. 2011, pp. 1952-1955, 2011.

[1] R. Melamud, et al., "Temperature-Insensitive Composite Micromechanical Resonators," JMEMS, Vol. 18, No. 6, pp. 1409-1419, 2009.

[2] J. C. Salvia, et al., "Real-Time Temperature Compensation of MEMS Oscillators Using an Integrated Micro-Oven and a Phase-Locked Loop," JMEMS, Vol. 19, No. 1, pp. 192-201, 2010.

[3] A. K. Samarao, F. Ayazi, "Temperature Compensation of Silicon Resonators via Degenerate Doping," IEEE Trans. Elec. Dev., vol. 59, no. 1, pp. 87-93, 2012.

[4] T. Pensala et al., "Temperature Compensation of Silicon MEMS Resonators by Heavy Doping," Int'l Ultras. Symp. 2011, pp. 1952-1955, 2011.

Narrow Gaps for Bulk-Mode Resonators

Eldwin Ng

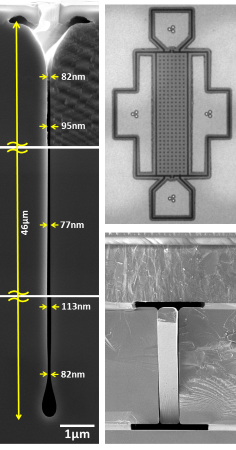

Higher frequency bulk-mode resonators are desired for lower phase noise. As the displacements for such modes are smaller than flexural modes, narrow transduction gaps (<300nm) are required to drive and sense such modes. A fabrication process for narrow trenches in single crystal silicon has been developed using a combination of deep reactive ion etching (DRIE) and selective epitaxial deposition [1]. Trenches of <100nm wide and over 45um deep (aspect ratio of >500:1) in single crystal silicon are demonstrated. Silicon bulk acoustic resonators (SiBARs) developed by the Ayazi group [2] are demonstrated in an epi-seal process with narrow gaps fabricated in single crystal silicon.

References

[1] E. J. Ng, et al., "Ultra-high aspect ratio trenches in single crystal silicon with epitaxial gap tuning," Hilton Head Conference, pp. 182-185, 2013.

[2] S. Pourkamali et al., "High-Q Single Crystal Silicon HARPSS Capacitive Beam Resonators With Self-Aligned Sub-100-nm Transduction Gaps", JMEMS, Vol. 12 No. 4, pp. 487-496, 2003.

[1] E. J. Ng, et al., "Ultra-high aspect ratio trenches in single crystal silicon with epitaxial gap tuning," Hilton Head Conference, pp. 182-185, 2013.

[2] S. Pourkamali et al., "High-Q Single Crystal Silicon HARPSS Capacitive Beam Resonators With Self-Aligned Sub-100-nm Transduction Gaps", JMEMS, Vol. 12 No. 4, pp. 487-496, 2003.

Nonlinear Operation

Yushi Yang

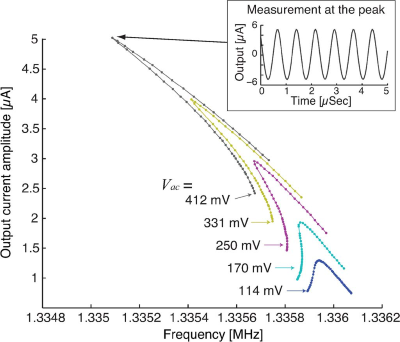

Resonators can be driven to higher amplitudes well into the nonlinear regime. Traditionally, this is not done as instabilities can occur in the open-loop case when resonators are operated above the critical vibration amplitude. However, in a closed-loop oscillator, resonators can be driven with much greater amplitudes stably. This improves the power handling performance and reduces the far-from-carrier phase noise.

References

[1] H. K. Lee, et al., "Stable Operation of MEMS Oscillators Far Above the Critical Vibration Amplitude in the Nonlinear Regime," JMEMS, Vol. 20, No. 6, pp. 1228-1230, 2011.

[1] H. K. Lee, et al., "Stable Operation of MEMS Oscillators Far Above the Critical Vibration Amplitude in the Nonlinear Regime," JMEMS, Vol. 20, No. 6, pp. 1228-1230, 2011.

Modeling of Energy Loss Mechanisms

Shirin Ghaffari

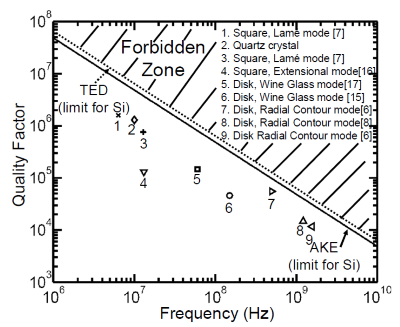

The quality factor of a resonator is a measure of the amount of energy dissipated. Often, high quality factor resonators are desired for low phase noise, motional impedance and power consumption - this means that energy loss has to be minimized. For MEMS resonators, some of the dominant energy loss mechanisms include gas damping, anchor loss, thermoelastic dissipation (TED) [1,2] and the Akhieser effect (AKE) [3]. TED and AKE are seen to place hard limits on the f Q product for silicon resonators as shown in the figure.

References

[1] R. N. Candler, et al., "Impact of Geometry on Thermoelastic Dissipation in Micromechanical Resonant Beams," JMEMS, Vol. 15, No. 4, pp. 927-934, 2006.

[2] A. Duwel, et al., "Engineering MEMS Resonators With Low Thermoelastic Damping," JMEMS, Vol. 15, No. 6, pp. 1437-1445, 2006.

[3] S. A. Chandorkar, et al., "Limits of quality factor in bulk-mode micromechanical resonators," 2008 IEEE MEMS, pp. 74-77, 2008.

[1] R. N. Candler, et al., "Impact of Geometry on Thermoelastic Dissipation in Micromechanical Resonant Beams," JMEMS, Vol. 15, No. 4, pp. 927-934, 2006.

[2] A. Duwel, et al., "Engineering MEMS Resonators With Low Thermoelastic Damping," JMEMS, Vol. 15, No. 6, pp. 1437-1445, 2006.

[3] S. A. Chandorkar, et al., "Limits of quality factor in bulk-mode micromechanical resonators," 2008 IEEE MEMS, pp. 74-77, 2008.

:: Gyroscopes

Chae Hyuck Ahn, Sarah Nitzan [Horsley Group, UC Davis]

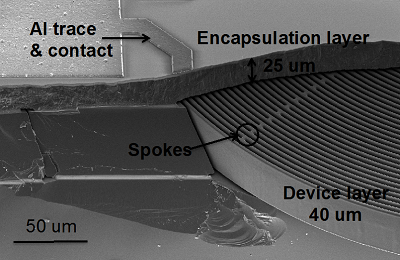

In addition to accelerometers, gyroscopes for measuring rotational velocity have been demonstrated in the epi-seal process. Based on the Disk Resonating Gyroscope (DRG) design [1], at least two degenerate mode shapes exist and the device is driven on one axis in one of the modes. Coriolis forces from the rotation induce a resonance in the second mode and this can be sensed.One issue with the DRG is the frequency split between the wineglass modes, due to the material anisotropy of (100) single crystal silicon. A good frequency match is desired for maximum energy transfer between the modes, as this results in large sensitivity. Having the device made of polysilicon reduces the frequency split, but causes roughening of the surface due to silicon migration [3]. The frequency mismatch in (100) silicon can be tuned away by modifying the design in layout - and we show that near-zero frequency splits can be achieved [4].

References

[1] D. A. Challoner, K. Shcheglov, "Isolated planar mesogyroscope," U.S. Patent #7168318, Jan 30, 2007.

[2] S. Nitzan, et al., "Epitaxially Encapsulated Polysilicon Disk Resonator Gyroscope," 2013 IEEE MEMS

[3] E.J. Ng, et al., "Ultra-stable epitaxial polysilicon resonators," Hilton Head 2012, pp. 271-274, 2012.

[4] C.H. Ahn, et al., "Mode-Matching of Wineglass Mode Disk Resonator Gyroscope in (100) Single Crystal Silicon," JMEMS, 24 (2), pp. 343-350, 2015.

[1] D. A. Challoner, K. Shcheglov, "Isolated planar mesogyroscope," U.S. Patent #7168318, Jan 30, 2007.

[2] S. Nitzan, et al., "Epitaxially Encapsulated Polysilicon Disk Resonator Gyroscope," 2013 IEEE MEMS

[3] E.J. Ng, et al., "Ultra-stable epitaxial polysilicon resonators," Hilton Head 2012, pp. 271-274, 2012.

[4] C.H. Ahn, et al., "Mode-Matching of Wineglass Mode Disk Resonator Gyroscope in (100) Single Crystal Silicon," JMEMS, 24 (2), pp. 343-350, 2015.

:: Stress/Strain Sensors

The resonant frequency of a beam changes with the applied axial stress. Resonating beams that are anchored at both ends (for example, the beams in a double-anchored double-ended tuning fork resonator) will measure a frequency change if the anchors are pulled apart or pushed together. This effect can be exploited to measure changes in film stress [1], or package stress [2].

References

[1] Y.Q. Qu, et al., "Using encapsulated MEMS resonators to measure evolution in thin film stress," Transducers 2009, pp. 1138-1141, 2009.

[2] C.-F. Chiang, et al. "Resonant Pressure Sensor with On-chip Temperature and strain sensors for error correction," IEEE MEMS 2013, pp. 45-48, Jan 2013.

[1] Y.Q. Qu, et al., "Using encapsulated MEMS resonators to measure evolution in thin film stress," Transducers 2009, pp. 1138-1141, 2009.

[2] C.-F. Chiang, et al. "Resonant Pressure Sensor with On-chip Temperature and strain sensors for error correction," IEEE MEMS 2013, pp. 45-48, Jan 2013.

:: Pressure Sensors

Chia-Fang Chiang

Diaphragms can be defined on the cap to measure pressure. A pressure change causes a deflection in the membrane of the diaphragm, which can then be measured capacitively or by using a strain-based resonant approach.More on Pressure Sensors

:: Thermometers

Eldwin Ng

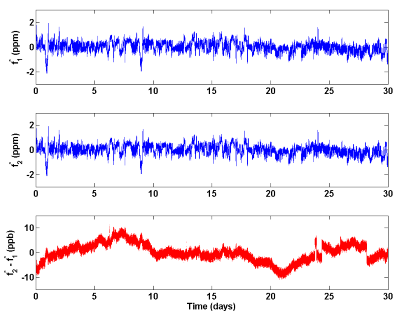

Since silicon as a material has a temperature dependence, these resonators can be used as thermometers [1-3]. By monitoring the resonant frequency shift with temperature, the temperature can be deduced. Resonators fabricated in the epi-seal process have been shown to be very stable - two resonators side-by-side track each other to within 10ppb over the course of a month, corresponding to a temperature noise of a fraction of a mC with 1s of integration time [3].

References

[1] C. M. Jha, et al., "High resolution microresonator-based digital temperature sensor," Applied Physics Letters, Vol. 91, No. 7, pp. 74101, 2007.

[2] M. A. Hopcroft, et al., "Using the temperature dependence of resonator quality factor as a thermometer," Applied Physics Letters, Vol. 91, No. 1, pp. 13505, 2007.

[3] E. J. Ng, et al., "Stability measurements of silicon MEMS resonant thermometers," 2011 IEEE Sensors Proceedings, pp. 1257-1260, 2011.

[1] C. M. Jha, et al., "High resolution microresonator-based digital temperature sensor," Applied Physics Letters, Vol. 91, No. 7, pp. 74101, 2007.

[2] M. A. Hopcroft, et al., "Using the temperature dependence of resonator quality factor as a thermometer," Applied Physics Letters, Vol. 91, No. 1, pp. 13505, 2007.

[3] E. J. Ng, et al., "Stability measurements of silicon MEMS resonant thermometers," 2011 IEEE Sensors Proceedings, pp. 1257-1260, 2011.

Magnetometers

in collaboration with Mo Li [Horsley Group, UC Davis]

Magnetometers have been successfully fabricated in the epi-seal process. Testing is currently underway.Contact Switches

in collaboration with Scott Lee and Kimberly Harris [Howe Group, Stanford]

Preliminary data show that maintaining an ultra-clean environment is critical for the reliability of contact switches. Results to be added soon.

Last updated on: Apr 16 2019